Overview

Abbuffen

In leather, refers to the slight removal of grain damage to produce a suede-like feel.

Grayling

A preparatory process for tanning. Through this step, the action of the liming chemicals destroys hair and epidermis or loosens them to such an extent that they can be easily removed mechanically.

Alcantara

the brand name of a non-woven microfiber fabric with a nubuck-like appearance. It is made of polyester microfiber and polyurethane and used as upholstery fabric.

Aniline leather

The leathers known as aniline leathers are dyed through with water-soluble aniline dyes. Aniline dyes dye transparently. They do not hide anything. Aniline dyes give the leather most of its natural properties. It remains pleasantly soft and grippy.

Grinding

Term for a leather processing. Depending on the needs and texture of the skin, the grain or the flesh side can be sanded to achieve the so-called velous effect.

Eject

A step in the production of leather. During drying, the leather contracts and then looks wrinkled. To eliminate existing wrinkles or puckers and to achieve a smooth surface, the leather is stretched and pushed out.

Band springs

Flat spiral springs used to support upholstered furniture.

Effilé

Border with edge of fringes or loops.

Border seam

An additional applied edging tape to secure the cut edge of the cover material.

Fascias

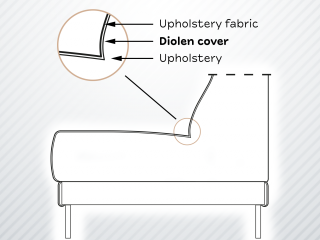

Serves as an upholstery cover to prevent chafing of the cover fabric.

Spring bands

Flat spiral springs with a width of approx. 1.5 mm. They are used as a resilient base for seat cushion or back cushion upholstery and as under-springing.

Spring core

Used to upholster fixed seats. Circumferential band steel frames stabilizing the spring core and spirals connecting the springs provide seating comfort.

Spring basket

For the suspension of chairs.

Greasing

The last operation in leather production before drying. This prevents the leather from drying out or becoming hard after tanning.

Flat springs

A type of spring with both tensile and compressive action. It is used for frame construction.

Flat fabric

Fabric fabrics coming from a flat loom with horizontal, flat warp.

Flame retardant finish

To reduce the flammability of textiles.

Flor

Velvet-like or nubby surface of textile fabrics.

Formpolster

Upholstery part with uniform density and compression hardness foamed in a single operation.

Cantilever

Chairs or armchairs with frame bent in S-shape, which slightly bounce when sitting.

Fungicidal equipment

Chemical treatment of textiles to protect them from fungal attack.

Functional fittings

Elements and mechanisms. In the case of upholstered furniture, they allow adjustability and changes in inclination and provide additional benefits.

Functional upholstered furniture

Upholstered furniture with special functions: Sofa with folding armrest, adjustable backrest.

Set

A set of upholstered furniture groups. For example, a sofa and two armchairs.

Tanning

Leather manufacturing process to make the leather imperishable and durable.

Gloss push

To achieve a smoothing of the leather and an increase in gloss, glass or agate rollers are passed over the grain layer of the leather by means of machines. A layer of wax is applied beforehand. Suitable for chrome or blank leather.

Belts

For the construction of upholstered furniture. Rubber belts are used for elastic back and seat upholstery, inelastic belts made of jute for the bottom upholstery.

Haptics

The term comes from the Greek expression for “tangible” and describes everything that is perceived through the sense of touch. So in the case of upholstery fabric, how it feels.

High back chair

An armchair with disproportionately high backrest from 105 to 110 cm.

Stool

A small piece of seating furniture without backrests.

Cover

A decorative textile throw for upholstered furniture.

Hydrophobing

Process step in leather production to make the leather water-repellent. For this purpose, the spaces between the fibers are closed with a waterproof substance.

Height repeat

The distance at which a fabric pattern is repeated in height, i.e. in the warp direction.

Jacquard

A fabric in which the patterns are not printed on, but are created by intricate weaving of the yarns. Named after the inventor Joseph-Maria Jacquard.

Jute belts

Narrow fabric strips of jute yarns for seat and back upholstery.

Cold foam

Cold foam is a polyurethane (PU or PUR) made from isocyanates and polyfunctional alcohols (polyols). Cold foam is also called HR (high resilient) foam because it can be produced with higher compression hardness than conventional hot foam.

Crosscut seam

A double seam where the protruding seam edges are narrow-edged topstitched.

Piping

A cord tied in a cloth ribbon.

Chain

Longitudinal thread and scaffold of textile fabrics.

Krispeln

A special type of leather processing to make the natural grains particularly apparent. Here, the wet leather is pulled over a sheet edge with the help of two rollers.

Köper

The twill weave is one of the three basic weaves. Its repeat goes over at least three warp and three weft threads. The weave results in the characteristic ribs running diagonally in the fabric.

Leather dyeing

The dyeing of the leathers is mainly done in rotating vats or in drum machines. The three methods: Aniline dyeing (transparent dyeing), semi-aniline dyeing (lightly pigmented leather) and the pigment dyeing (opaque dyeing).

Lightfastness

The evaluation of the color fastness of textiles to daylight. Lightfastness is classified on a scale of 1 to 8, with 1 being the worst and 8 the best light rating. The significant change in pattern and color in relation to the type dyeing is observed.

Millen

A working step in leather processing. In the mill barrel, the leathers are turned dry, i.e. without water, and thus softened. This produces a particularly soft leather quality with a pleasant, full feel. Probably the best-known type of milled leather is nappa leather.

Moiré

Upholstery fabrics with patterns reminiscent of wood grains or water waves.

Natural fiber

Material obtained from animal hair or plants, such as cotton, jute, linen, virgin wool and silk.

Kidney support

A pad protrusion in the back of an upholstered piece of furniture. At the level of the lumbar vertebrae, the kidney support increases the comfort of the seat.

Nylon

Generic term for polyamide fibers

Ottoman

A sofa without a proper backrest and with only one armrest.

PUR foam

Polyurethanes (PU, DIN abbreviation: PUR) are plastics or synthetic resins resulting from the polyaddition reaction of diols or polyols with polyisocyanates. For the production of flexible polyurethane (PUR) foams, the liquid base raw materials polyalcohols, or polyols, and polyisocyanates, or isocyanates, are used in a precisely defined ratio. Polyaddition means that alcohol (polyol) and isocyanate, two organic compounds, are combined in a chemical reaction process to form long-chain (macro) molecules. The addition of water leads to the formation of CO2, which causes the mixture to foam up and creates the cell structure of the foam.

Pilling

Knotting of upholstery fabrics made of mixed fabrics (e.g.: virgin wool). Occurs due to use, rubbing of the surface. The nodule fibers are called pills.

Upholstered frame

The framework and therefore the foundation of any upholstered furniture, which varies in shape, material used and structure.

Vlies

Protective layer between the foam and the cover. It prevents rubbing through of the upholstery fabric from the bottom side and is mainly made of polyester.

Rapport

A constantly repeating pattern in the fabric.

Volume weight

Designation for the quality of foam in kilograms per cubic meter. The rule of thumb: the higher the density, the better the properties of use.

Recamiere

A sofa with one arm and one back, named after Julie Recamiere 1777 – 1849.

Rubbing fastness

Designation for the resistance of the color of upholstery fabrics to rubbing off or bleeding (staining) onto other textiles. The assessment is made in 5 levels (fastness numbers), where level “5” means a very high rub fastness and level “1” a very low one.

Relax armchair

Generic term for an armchair with functions such as back or foot position adjustment. The positions can be adjusted manually or by motor.

Saddle pad

A kind of valance made from the upholstery fabric of upholstered furniture, which forms the bottom finish.

Scrub resistance

The abrasion resistance indicates the durability of an upholstery fabric and is determined in the abrasion test.

Scrubbing cycles

Rubbing tours are a measure of the resistance of fabrics. The higher the number of tours, the higher the resistance to abrasion and wear. Testing is carried out using the Martindale method. In this test on a Martindale testing machine, the fabric is rubbed against a worsted fabric to simulate wear. The machine records the number of friction cycles (or rubbing strokes) to which the fabric has been subjected until a physically definable end point is reached. This endpoint is reached when three yarns of the fabric are worn through to the point of breakage, and the rub count is then the number of cycles at the time of breakage.

Grinding

A working process of leather processing. The grain or flesh side of the leather is sanded to achieve a velvety or suede-like effect.

Silk

Protein fiber from the hardened secretion of the silkworm.

Semi-aniline leather

The combination of pigment dyes and aniline dyeing. Upholstery leather in pigmented, i.e. muted, finish is sprayed over with a covering protective color layer. Semi-aniline leather is smooth or embossed in the surface.

Exposed wood frame

A type of upholstered frame in which essential wooden parts remain visible, such as the armrests.

Seat height

The seat height of upholstered furniture is measured from the highest point of the seat to the floor. It is between approx. 38 and 46 cm.

Seat mirror

Iridescent stains on velour fabrics caused by heat and body pressure.

Seat depth

The seat depth is measured the area from the front edge of the seat to the backrest. It is between approx. 50 and 56 cm.

Split leather

Depending on the animal and the area of the body, a hide has different thicknesses, this is brought to a uniform density by splitting. This creates scar split (upper part of the skin) middle split and flesh split (lower part of the skin).

Tampon

A step in leather processing in which the leather is wiped with a dye solution and the raised areas of the surface are dyed.

Transparency dyeing

A type of leather dyeing (aniline leather) in which water-soluble dye substances are absorbed into the hide fiber and dye the leather. The pores remain open and natural features are preserved.

Suspension

The basis of the upholstered furniture structure. Most often used steel wave springs, spring core or elastic belts.

Velour

The French term for pile fabrics. This is a fabric with an upright or laid pile.

Suede leather

A type of cowhide in which the reverse side is sanded and processed with the roughened side facing outward (suede leather).

Viscose

A man-made fiber with natural properties obtained from cellulose.

Soaking

A step in the processing of leather. The leather is soaked in water and cleaned, soluble proteins are washed out and the leather becomes supple.

Xenotest

Test for determining the lightfastness of textile dyeings. In this test, fabrics are placed under a xenon lamp that resembles daylight.

Decorative nails

Visible fastening of clamping parts or decorative accentuation of armrests, nickel-plated, brass-plated or plastic, with smooth heads or ornamented.

Cylinder spring core

Cylindrical spring cores consist of surface-finished cylindrical steel springs which are twisted into one another and joined to form a spring unit.